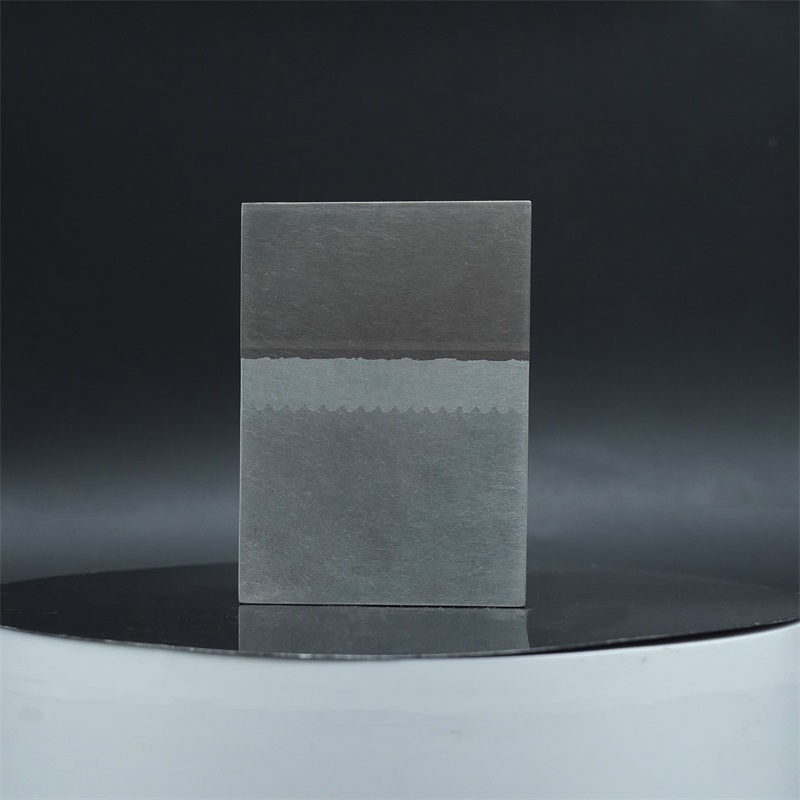

Description of titanium clad steel plate:

Titanium nickel-clad plate is a cladding material composed of titanium and nickel, with excellent corrosion resistance and high strength. Titanium has high corrosion resistance, but its low strength makes it unsuitable for high stress areas. As a clad plate, nickel has the advantages of excellent mechanical properties, good corrosion resistance, high strength, easy processing, good electrical conductivity, good wear resistance and good chemical stability. The titanium nickel-clad plate combines the unique advantages of the two metals. Therefore, it has been widely used in various fields, especially electronics, electric power, construction, transportation, aerospace, etc.

Features of titanium clad steel plate:

Good corrosion resistance: Nickel alloys have very high corrosion resistance to various corrosive media (acid, alkali, salt, seawater, atmosphere, etc.) in the atmosphere, water, steam, mud and other media, especially for alkaline media, Even in high temperature, it can maintain high corrosion resistance.

High strength: The high strength of nickel alloys is usually due to the addition of alloying elements, such as copper, iron, manganese, chromium, silicon, magnesium, etc., which can increase the strength of the alloy and maintain high stability.

Good conductivity: Nickel alloy has good conductivity and low resistivity and is widely used in electronics, electric power, aerospace, and other fields.

Good wear resistance: Although the wear resistance of nickel alloy is not as good as that of iron-based alloys, its wear resistance is still very good, especially under high speed and temperature conditions; it can still maintain high wear resistance.

Good chemical stability: Nickel alloy has good chemical stability at high temperatures and can resist the corrosion of various media (acid, alkali, salt, etc.).

Applications of titanium clad steel plate:

The application of titanium nickel-clad plate includes but is not limited to the following aspects:

Marine engineering field: Titanium nickel-clad plates can manufacture marine engineering equipment, such as seawater desalination equipment, pipelines for offshore platforms, propellers for ships, etc. These equipment can operate in the marine environment to ensure the reliability and safety of the equipment.

Medical equipment field: Titanium nickel-clad plates can be used to manufacture medical equipment, such as artificial joints, cardiac pacemakers, endoscopes, etc. This equipment can help patients receive better treatment and reduce pain and discomfort.

Aerospace field: Titanium nickel-clad plates can manufacture aerospace equipment, such as aircraft engines, satellite antennas, solar panels, etc. These equipment can operate in extreme environments to ensure the reliability and safety of the equipment.

Electric power field: Titanium nickel-clad plates can manufacture power equipment, such as transformers, cables, etc. These equipment can operate in high-voltage and highly corrosive environments to ensure the reliability and safety of the equipment.

Military field: Titanium nickel-clad plates can manufacture military equipment, such as aero engines, missiles, tanks, etc. This equipment can operate in high temperatures and strong corrosive environments to ensure the reliability and safety of the equipment.

Grade of Titanuim Nickel Clad Plate:

TAI, TA2, TA3, TA8, TA9, TA10, TA18, N4, N6, NCu28-2.5-1,5, NCu30

Standard of Titanium Nickel Clad Plate:

NB/T47002.3-2009,GBT8547-2006

Package of Titanium Nickel Clad Plate:

According to product characteristics and customer needs.

Remark of Titanium Nickel Clad Plate:

Please provide detailed technical requirements to facilitate communication and determine the solution.

Titanium clad steel plate supplier-TRUNNANO:

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12 years of experience providing super high-quality clad plates, clad rods, clad tubes, etc.

If you are looking for a high-quality Titanium nickel-clad plate, please feel free to contact us and send an inquiry.