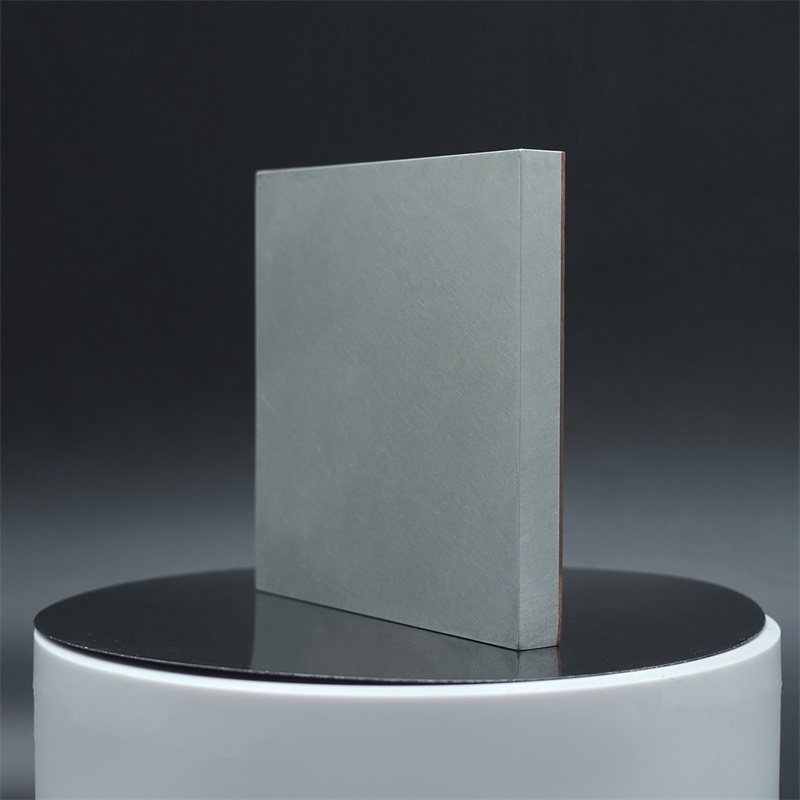

What is Nickel/Steel Clad Plate:

Nickel/steel clad plate is a new type of metal structure material. It is first to physically splice the steel plate into a specific geometric shape, then compound it with hard nickel alloy, and combine it into a whole through welding and other processes. This material combines the advantages of stainless steel and steel, has excellent corrosion resistance, high strength, good cold formability and easy welding, and can be widely used in marine engineering, industrial production and other fields.

Advantage/Characteristics of Nickel/Steel Clad Plate:

Excellent corrosion resistance: The surface of the nickel-steel clad plate is made of stainless steel, so it has strong corrosion resistance.

Good mechanical properties: Nickel-steel composite panels have high tensile strength and can withstand large deformation and tensile strength.

Good high temperature resistance: Nickel steel clad plate can still maintain high strength and excellent corrosion resistance at high temperature.

Beautiful surface: Nickel-steel composite panels have a gorgeous surface of stainless steel, which can meet customers' requirements for appearance.

Good weldability: Nickel-steel composite panels can be used for various welding operations, which is convenient and quick, and improves production efficiency.

Good processability: Nickel-steel composite panels can be cut, drilled, bent and other processing operations, which is convenient for customers to use.

Low cost: The production and processing cost of nickel steel clad plate is low, which can effectively reduce the production cost of customers.

Applications of Nickel/Steel Clad Plate:

Petrochemical field: Nickel/stainless steel composite plates can be used to make reactors, heat exchangers, separators and other equipment, and are used in petrochemical, oil refining, chemical and other fields.

Electric energy field: Nickel/stainless steel composite plates can be used to make separators for electrolytic cells, electrode plates, guard plates for generators and other equipment, and are used in fields such as electric power and energy.

Medical device field: Nickel/stainless steel composite plate can be used to make medical devices, such as oxygen generators, lung washing machines, etc., used in medical and health care and other fields.

Architectural decoration field: Nickel/stainless steel composite board can be used to make anti-theft doors, automatic doors, wall switches and other equipment, and is used in construction, decoration and other fields.

Transportation field: Nickel/stainless steel composite plates can be used to make chassis, body, frame and other components of automobiles, trains, airplanes and other vehicles, and are used in transportation, transportation and other fields.

Food and beverage field: Nickel/stainless steel composite plate can be used to make food and beverage equipment and utensils such as cans and beverages, and is used in food, beverage and other fields.

Aerospace field: Nickel/stainless steel composite plates can be used to make structural parts and components of aircraft, rockets and other aerospace vehicles, and are used in aviation, aerospace and other fields.

Grade of Nickel/Steel Clad Plate:

N4.N6.NCu28-2.5-1.5.NCu30.NS312.NS336.NS142

Q245R.Q345R.15CrMoR.20MnMO, 15CrMo.09MnNiDR.16MnD. 09MnNiD

Standard of Nickel/Steel Clad Plate:

NB.T 47002.2-2009

SA-265

Package of Nickel/Steel Clad Plate:

According to product characteristics and customer needs.

Remark of Nickel/Steel Clad Plate:

Please provide detailed technical requirements to facilitate communication and determine the solution.

Nickel/Steel Clad Plate supplier-TRUNNANO:

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality clad plate, clad rod, clad tube, etc.

If you are looking for high-quality Nickel/Steel Clad Plate, please feel free to contact us and send an inquiry.