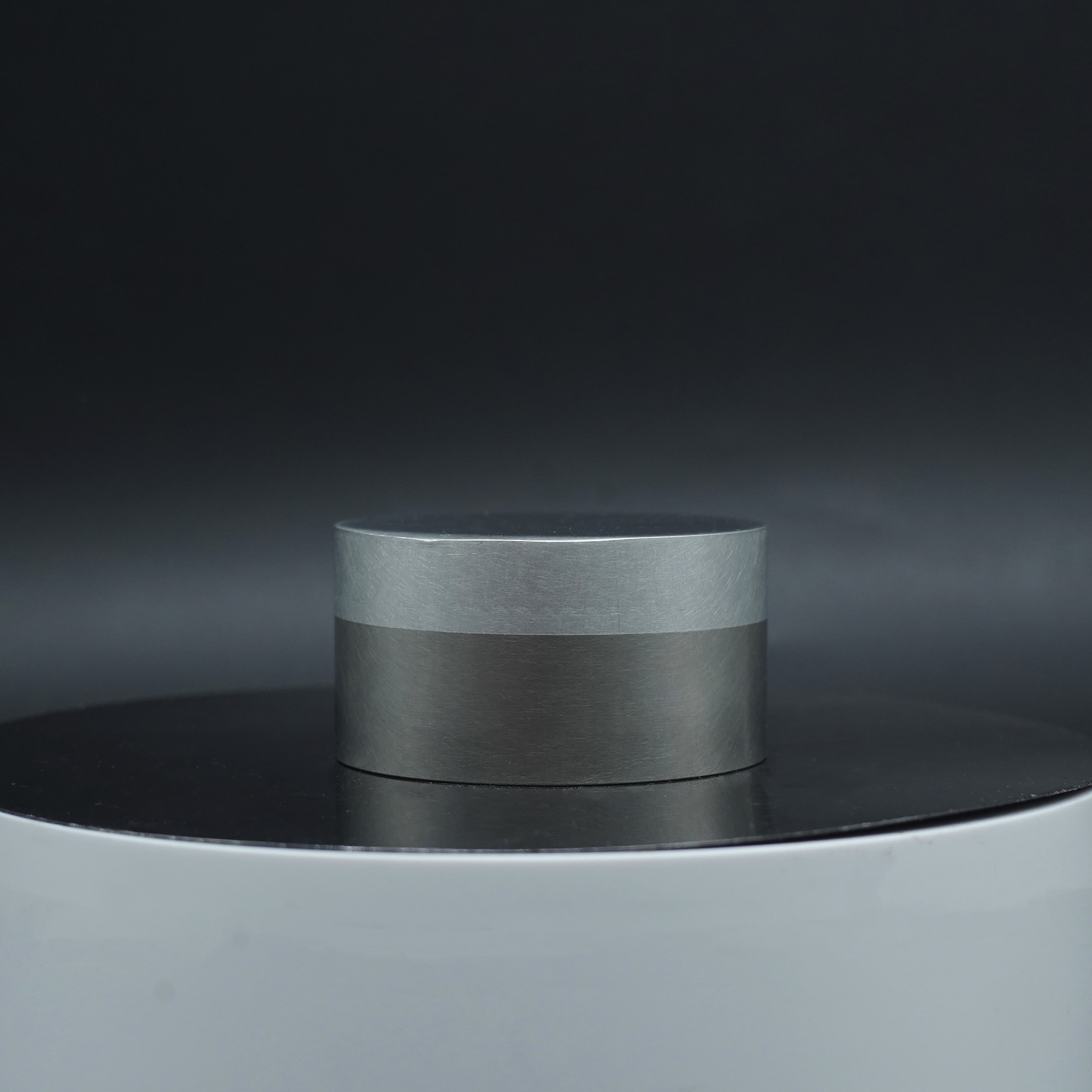

What is Aluminum Stainless Steel Clad Plate?

Aluminum stainless steel clad plate is a clad material composed of aluminum alloy plate and stainless steel plate, and its structure is composed of aluminum alloy plate and stainless steel plate. Aluminum stainless steel clad plates have the advantages of light weight, corrosion resistance, high strength, high temperature resistance, wear resistance, fatigue resistance, and good self-lubrication performance, and are widely used in construction, aviation, transportation, electronics, medical and other fields.

Features of Aluminum Stainless Steel Clad Plate:

The main features of aluminum stainless steel clad plates are as follows:

Light weight: The weight of the aluminum stainless steel clad plate is only about 1/3 of the traditional pure aluminum panel, which can greatly reduce the load of the building and reduce the cost of the structure.

Corrosion resistance: The surface of the aluminum stainless steel clad plate has good corrosion resistance, which can effectively prevent the erosion of buildings by corrosive gases such as acid rain and salt spray.

High strength: Aluminum stainless steel clad plates have very high strength and can be made into various structural parts or parts with complex shapes, uneven thickness and heavy loads.

High temperature resistance: Aluminum stainless steel clad plates can withstand high temperatures up to 1000°C, so they are very useful in many high temperature applications.

Wear resistance: The wear resistance of aluminum stainless steel clad plates is very good, which can effectively reduce friction, reduce wear and tear, and prolong the service life of buildings.

Conductivity: Aluminum conducts electricity even better than copper.

Characteristics of aluminum-clad steel explosion composite plate

Light weight and high strength: The aluminum clad steel plate explosion composite plate adopts an aluminum alloy plate and steel plate for composite, so it has the lightweight and high strength characteristics of aluminum plate, and at the same time also has the strength and corrosion resistance of steel plate. This material's lightweight and high strength can reduce structural weight and improve structural efficiency.

Good processing performance: The aluminum-clad steel explosion composite plate can be plastic processed, has excellent plasticity and flexibility, can be bent, tensile, stamped, and other processing, and is suitable for manufacturing various complex mechanical parts.

Good thermal conductivity: An aluminum plate has excellent thermal conductivity, so an aluminum-clad steel explosion composite plate also has good thermal conductivity, can effectively transfer heat, and is suitable for manufacturing radiators, heating elements and so on.

Corrosion resistance: The steel plate has good corrosion resistance, while after special treatment, the aluminum plate also has a certain degree of corrosion resistance, so the aluminum clad steel explosion composite plate has good corrosion resistance, suitable for manufacturing valves, pipelines and other requirements of corrosion-resistant components.

Environmental protection and energy saving: Aluminum-clad steel explosion composite plate can be recycled and has the characteristics of environmental protection and energy saving, in line with the current requirements of sustainable development of society.

Grade of Aluminium Clad Steel Plate

Q/XB1906

Application of Aluminum-clad steel explosion composite plate

Architectural decoration works: The aluminum-clad steel explosion composite plate has the characteristics of being lightweight and high strength, easy to process, beautiful and generous, can be made into a variety of decorative lines, sculptures, railings, etc., and is widely used in architectural decoration projects.

Radiator manufacturing: due to the aluminum-clad steel explosion composite plate having good thermal conductivity and corrosion resistance, it can be used to manufacture automobiles, electronic equipment, and other occasions of radiators to improve the reliability and service life of the equipment.

Pipeline manufacturing: Aluminum-clad steel explosion composite plate has good corrosion resistance and processing performance and can be used to manufacture water pipes, gas pipes, oil pipelines, and other pipeline equipment.

Mechanical parts manufacturing: aluminum clad steel explosion composite plate has excellent plasticity and flexibility and can manufacture various mechanical parts, such as gears, bushings, screws, and so on. At the same time, its strength and corrosion resistance also make it in the manufacture of mechanical parts has a wide range of application prospects.

Medical device manufacturing: Due to its good thermal conductivity and corrosion resistance, aluminum-clad steel explosion composite plates can manufacture medical devices, such as surgical instruments, implants, and so on. At the same time, its lightweight and high strength characteristics also make the application in the medical field have advantages.

Grade of Aluminum Stainless Steel Clad Plate:

1A97, 1A93, 1A90, 1A85, 1070, 1060, 5083, S11306, S11348, S30408, S30403, S32168, S31603, S31703, S22053, S39042

Standard of Aluminum Stainless Steel Clad Plate:

GBT 8546-2007

Package of Aluminum Stainless Steel Clad Plate:

According to product characteristics and customer needs.

Remark of Aluminum Stainless Steel Clad Plate:

Please provide detailed technical requirements to facilitate communication and determine the solution.

Aluminum Stainless Steel Clad Plate supplier-TRUNNANO:

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality clad plate, clad rod, clad tube, etc.

If you are looking for high-quality aluminum stainless steel Clad Plate, please feel free to contact us and send an inquiry.