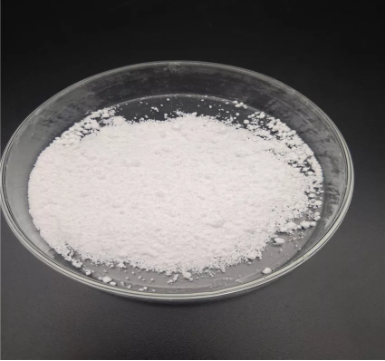

| Spherical quartz powder Spherical SiO2 Properties | |

| Other Names | Fused quartz, spherial quartz, spherical SiO2, silica |

| CAS No. | 7631-86-9 |

| Compound Formula | SiO2 |

| Molecular Weight | 60.09 |

| Appearance | White Powder |

| Melting Point | 1,600° C (2,912° F) |

| Solubility in water | N/A |

| Density | 2533 kg/m3 |

| Purity | 99.5-99.9% |

| Particle Size | 10-30nm |

| Boling point | 2,230° C (4,046° F) |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | 59.9668 g/mol |

| Monoisotopic Mass | 59.967 Da |