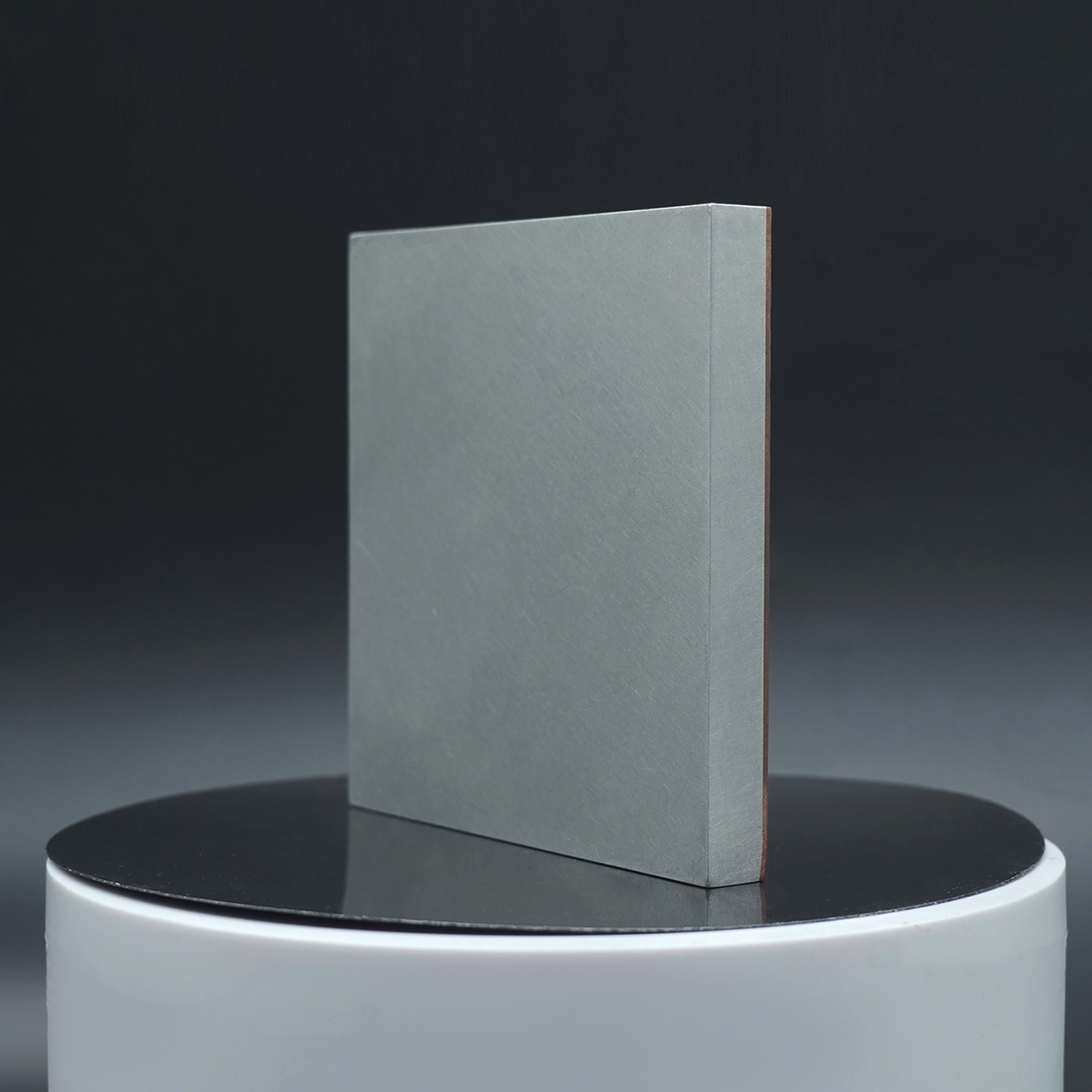

What is zirconium Steel composite plate zirconium clad plate?

Zirconium/steel composite plate is a new type of bimetallic composite material in which zirconium is the cladding and steel is the base layer. It combines the advantages of zirconium and steel with the excellent corrosion resistance of zirconium and the strength and stability of steel.

Zirconium/steel composite plate is a kind of material used in construction and engineering structures, with a steel plate as the base layer, pickled zirconium/steel composite plate or tailor-welded zirconium/steel composite plate as the cladding layer, and explosively welded method to connect the two boards.

Features of zirconium Steel composite plate zirconium clad plate:

Strong corrosion resistance: Because zirconium can react with oxygen in the air to generate a dense passivation film at room temperature, zirconium/steel composite plate has better corrosion resistance than stainless steel, titanium, and nickel alloys for most of the organic and inorganic acids, strong bases, molten salts, and other media.

Good mechanical properties and thermal conductivity: the mechanical properties and thermal conductivity of zirconium and steel are better, making zirconium/steel composite plates have a broad application prospect in the fields of pressure vessels, heat exchanger tube plates, tower components, and pipelines.

Resource-saving and cost reduction: zirconium/steel composite plates prepared by explosion welding technology can comprehensively utilize the advantages of zirconium, steel, stainless steel, tantalum, and titanium, thus reducing the material price and improving the material strength.

In terms of application, zirconium/steel composite plate is mainly used for high-end zirconium and zirconium alloy composite plates in large-scale chemical and nuclear industries projects to meet special corrosion-resistant requirements. In addition, it can also be used to manufacture pressure vessels, pipelines, and other fields with excellent corrosion resistance and high strength properties.

The advantages of zirconium Steel composite plate zirconium clad plate include:

Excellent corrosion resistance: Zirconium/steel composite panels have good corrosion resistance in media such as acid, alkali, salt, and seawater and can maintain their size and strength for a long time.

High strength: Zirconium/steel composite panels have high strength and can withstand large loads and stresses, so they are widely used in various engineering structures and buildings.

Good heat resistance: Zirconium/steel composite panels can still maintain their strength and stability in high-temperature environments and can be used in engineering structures and equipment in high-temperature environments.

Good engineering performance: zirconium Steel composite plate zirconium clad plate has good processing and welding performance and can be easily cut, drilled, welded, and other processing operations, so it is widely used in various engineering structures and buildings.

Environmental protection performance: Zirconium/steel composite panels do not produce harmful gases and pollutants, so they are considered an environmentally friendly and sustainable material.

Zirconium Steel composite plate zirconium clad plate have been widely used in many fields, including but not limited to the following aspects:

Ocean engineering: zirconium/steel composite panels are used in pipelines, pump casings, hulls, seawater desalination equipment, etc., in ocean engineering. Due to its excellent corrosion resistance and high strength, zirconium/steel composite panels have become important materials in marine engineering.

Nuclear power engineering: Zirconium/steel composite plates are used in nuclear power engineering for radiation protection and anti-corrosion materials, such as pressurized water reactor cores and voltage regulator internals.

Chemical engineering: zirconium/steel composite panels are used to manufacture pipes, reactors, tank cars, and other equipment in chemical engineering. Due to its good corrosion resistance and high-temperature performance, zirconium/steel composite panels have been widely used in chemical engineering.

Other fields: zirconium/steel composite panels can also be used in petroleum, metallurgy, military armor, and other fields

In general, zirconium/steel composite plate is a very excellent material with high application value and has been widely used in many fields to meet various needs.

Package of zirconium Steel composite plate zirconium clad plate:

According to product characteristics and customer needs.

Remark of zirconium Steel composite plate zirconium clad plate:

Please provide detailed technical requirements to facilitate communication and determine the solution.

Zr Steel zirconium Steel composite plate zirconium clad plate supplier - TRUNNANO:

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12 years of experience providing super high-quality clad plates, clad rods, clad tubes, etc. If you are looking for a high-quality Zr Steel zirconium Steel composite plate zirconium clad plate, please feel free to contact us and send an inquiry.