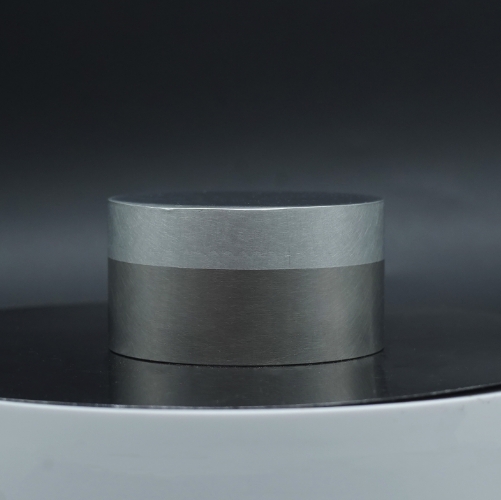

What is Nickel Clad Stainless Steel Plate?

Nickel-plated stainless steel plate is a new type of stainless steel composite material with a nickel metal layer plated on the surface of stainless steel. In addition to the advantages of stainless steel, this material is also decorative and corrosion-resistant and is widely used in construction, decoration, automobile, electronics, medical and other fields.

Nickel-plated stainless steel plate, as a stainless steel composite material with excellent corrosion resistance, decorative and radiation resistance, is widely used in construction, decoration, automotive, electronic medical and other fields. With the continuous progress of science and technology and the continuous improvement of application demand, nickel-plated stainless steel plates will be further developed in high performance, green environmental protection, customization and intelligence.

Metal clad plate refers to the board covered with another metal, which saves resources and reduces cost without reducing the use effect (anti-corrosion performance, mechanical strength, etc.).

The cladding methods usually include explosive cladding, explosive rolling cladding, rolling cladding, and so on.

According to the appearance, the composite material can be divided into the composite plate, composite pipe, composite bar, etc.

Physical and chemical properties of nickel-plated stainless steel plate:

Nickel-plated stainless steel plate is a layer of nickel metal deposited on the surface of stainless steel by the electroplating process, so it has the following characteristics:

Corrosion resistance: nickel-plated stainless steel plate has good corrosion resistance, especially to corrosion of acidic media such as chloride ions, and can maintain long-term corrosion resistance in marine, industrial, and urban environments.

Decorative: nickel-plated stainless steel plate has a bright and clean surface with good metallic texture, which can present an elegant and noble temperament. It is widely used in various decorative fields.

Easy processing: nickel-plated stainless steel plate can be cut, bent, welded, and other processing operations like stainless steel, and the surface will not be affected.

High-temperature performance: nickel-plated stainless steel plate has good high-temperature performance, can be used at higher temperatures, and high-temperature strength and creep properties are also good.Radiation resistance: nickel-plated stainless steel plate has a certain protective effect on X-ray and γ-ray so it can be used for manufacturing medical equipment and nuclear industry equipment.

Preparation process of nickel-plated stainless steel plate

The preparation process of nickel-plated stainless steel plate mainly includes the following steps:

Pretreatment: the stainless steel surface is polished, degreased, pickled and other treatments to improve the surface finish and cleanliness.

Electroplating: Put the pre-treated stainless steel plate into the electroplating tank and deposit a nickel metal layer on the stainless steel surface through an electrochemical reaction.

Post-treatment: the electroplated stainless steel plate will be cleaned, dried, and other treatments to remove surface impurities and moisture to improve product quality.

Grade of Nickel Clad Stainless Steel Plate

NB/T 47002.2

ASME SA265

Applications of Nickel Clad Stainless Steel Plate

Chlor-Alkali, Chemistry, Papermaking

Nickel-plated stainless steel plate has a wide range of applications; the following are its main areas of application:

Architectural field: nickel-plated stainless steel plate can be used for internal and external decoration of buildings, such as curtain walls, doors, windows, railings, staircases, elevators, etc. so that the buildings are more beautiful and durable.

Decorative field: nickel-plated stainless steel plates can be made into various decorative items, such as sculptures, reliefs, ornaments, etc., used to beautify the urban environment and home decoration.

Automotive field: nickel-plated stainless steel plate can be used in the manufacture of automobile parts, such as automobile shells, automobile wheels, etc., which can improve the appearance quality and corrosion resistance of automobiles.

Electronic field: nickel-plated stainless steel plate can be used to manufacture electronic products, such as circuit boards, connectors, terminals, etc., and can improve the quality of products and corrosion resistance.

Medical field: nickel-plated stainless steel plate can be used to manufacture medical equipment and components, such as surgical instruments, pharmaceutical equipment, medical equipment, etc., and can improve the corrosion resistance and health and safety of the equipment.

Other fields: nickel-plated stainless steel plate can also be used in petroleum, chemical, food, and other fields and can be manufactured in tanks, pipelines, valves, and other equipment to improve the corrosion resistance and service life of the equipment.

Package of Nickel Clad Stainless Steel Plate

According to product characteristics and customer needs.

Remark of Nickel Clad Stainless Steel Plate

Please provide detailed technical requirements to facilitate communication and determine the solution.

Nickel Clad Stainless Steel Plate supplier-TRUNNANO:

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12 years of experience in providing super high-quality clad plates, clad rods, clad tubes, etc.