| Product Name | Content | Particle Size | True Density | Bulk Density | Color |

| glass micro spheres | Borosilicate glass | 5- 100um | 0.12-0.70 g/cm3 | 0.10-0.40 g/cm3 | White |

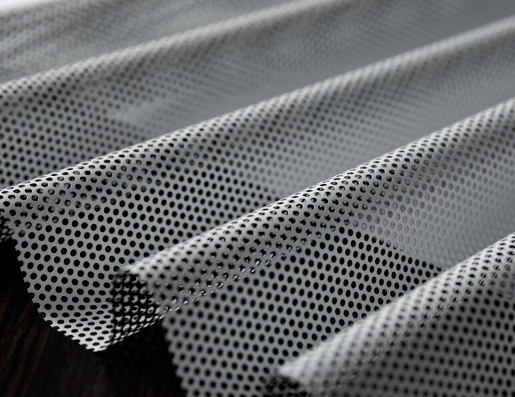

Hollow glass beads are tiny particles of lightweight, low-density, spherical structure, which are widely used in many fields due to their unique design and properties.

Lightweight Filler Material

Hollow glass beads(glass micro spheres) are widely used as lightweight filler materials in plastics, rubber, coatings and other products due to their light and low-density characteristics. These products usually need to reduce weight cost, improve performance, etc.; hollow glass beads can meet these requirements. In plastic products, hollow glass beads can be used as reinforcing filler material to enhance the products' strength, rigidity and weather resistance. In rubber products, hollow glass beads can be used as reinforcing filler material to improve abrasion resistance, tear-resistance and aging resistance. In coatings, hollow glass beads can be used as pigment filler to improve the covering power and transparency of coatings.

Heat Insulation Material

As hollow glass beads(glass micro spheres) have good thermal insulation properties, they can be used to manufacture thermal insulation materials, such as glass wool, vacuum insulation boards and so on. These materials are lightweight, efficient, environmentally friendly, and widely used in construction, aerospace, and other fields. In the field of construction, hollow glass beads can be used to manufacture lightweight thermal insulation and heat preservation boards, which have excellent thermal insulation and heat preservation effects and can effectively reduce the energy consumption and temperature fluctuations of buildings. At the same time, this kind of board also has the advantages of lightweight and environmental protection, which can reduce environmental impact. In the aerospace field, hollow glass beads can be used to manufacture thermal insulation materials for aircraft shells and thermal protection materials for spacecraft. These materials need to maintain stable performance in a variety of complex environments, such as high temperature, low temperature, vacuum, etc. Hollow glass beads are able to meet these requirements due to their unique structure and properties.

Electromagnetic wave shielding materials

Hollow glass beads(glass micro spheres) have good transmittance to electromagnetic waves and can be used to manufacture electromagnetic wave shielding materials, such as electromagnetic wave absorbing materials and electromagnetic wave protective clothing. These materials have important application value in electronic equipment, aerospace and other fields. In the field of electronic equipment, hollow glass beads can be used to manufacture electromagnetic wave-absorbing materials and electromagnetic wave protective clothing. Electromagnetic wave-absorbing materials can absorb electromagnetic waves and convert them into heat or other forms of energy, reducing the harm of electromagnetic waves to the human body. Electromagnetic wave protective clothing can protect workers from electromagnetic wave hazards, especially when working in high-frequency electromagnetic fields, and they need to take additional protective measures.

Reinforced Composites

Hollow glass beads(glass micro spheres) can be used as reinforcement in composite materials such as glass fiber-reinforced plastics and carbon fiber-reinforced resins due to their high strength, high rigidity and good chemical resistance. These composites are widely used in aerospace, automotive, sports equipment and other fields. In the aerospace field, hollow glass beads can be used as reinforcement in composite materials to improve the strength, rigidity and weather resistance of the material. For example, in the manufacture of aircraft parts, when using hollow glass beads, reinforced composite materials can significantly improve the strength and weather resistance of parts to extend the service life of the details. In the automotive field, hollow glass beads can be used as a reinforcement corresponding to the manufacture of automobile body chassis and other components to improve the strength of the elements and durability and other properties, such as in the manufacture of the automobile body when the use of hollow glass beads reinforced composite materials can make the car body For example, the use of hollow glass beads reinforced composites in the manufacture of automobile body can make the body stronger and lighter and have good energy-saving effect to improve the fuel economy and power performance of the automobile.

Drug Carrier

A drug carrier is a substance that can slowly release drugs into the human body. A drug carrier needs to have good biocompatibility and safety at the same time; the release rate and concentration of the drug also need to be precisely controlled by hollow glass beads as a drug carrier has the unique advantages of spherical shape and smooth surface characteristics that make it an ideal choice of drug carriers through the drug encapsulated in the hollow glass beads can be realized on the slow release and controlled release of the drug this kind of drug carrier can be used to achieve the slow release and controlled release of the drug. By encapsulating the drug in hollow glass beads, it can realize its slow waiver and controlled release. This kind of drug carrier has a significant application value in the field of drug delivery and controlled release of drugs.

Catalyst carrier

A catalyst is a substance that accelerates the reaction speed in a chemical reaction. Usually, it needs to be evenly dispersed in the reactants to play the best role. Hollow glass beads can be used as a catalyst carrier due to their high surface area and good chemical stability. Loading the catalyst on hollow glass beads can improve the dispersion and stability of the trigger and thus enhance the efficiency of the catalytic reaction. This catalyst carrier has essential application value in chemical and environmental protection.

Packing & Shipping of Hollow Glass Sphere Hollow Glass Beads(glass micro spheres):

We have many different kinds of packing which depend on hollow glass spheres quantity.

Hollow glass spheres packing: 1kg/bag, 25kg/barrel, or 200kg/ barrel.

Hollow glass spheres shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including boride powder, nitride powder, graphite powder, sulfide powder, 3D printing powder, etc.

If you are looking for high-quality Hollow Glass Microspheres, please feel free to contact us and send an inquiry. ([email protected])

Hollow Glass Spheres Properties |

||

| Other Names | Hollow Glass Beads(glass micro spheres) | |

| CAS No. | N/A | |

| Compound Formula | N/A | |

| Molecular Weight | N/A | |

| Appearance | White Powder | |

| Melting Point | N/A | |

| Boiling Point | N/A | |

| Density | 0.12-0.70 g/cm3 | |

| Solubility in H2O | N/A | |

| Exact Mass | N/A | |

Hollow Glass Spheres Health & Safety Information |

||

| Signal Word | N/A | |

| Hazard Statements | N/A | |

| Hazard Codes | N/A | |

| Risk Codes | N/A | |

| Safety Statements | N/A | |

| Transport Information |

|

|