About 3D Printing Alloy CoCrW Powder:

Cobalt-chromium-tungsten alloy (CoCrW) is one of the Stellite alloys. Stellite alloy is a hard alloy that can withstand various types of wear, corrosion and high-temperature oxidation. It is commonly referred to as a cobalt-based alloy. CoCrW can resist all kinds of wear, corrosion and oxidation at high temperatures. According to the composition of the alloy, it can be made into welding wire, used for hard surface surfacing, thermal spraying, spray welding powder. Stellite was originally a binary cobalt-chromium alloy and later developed into a ternary composition of cobalt-chromium-tungsten. Cobalt-chromium-tungsten alloy is a kind of alloy with cobalt as the main component, containing a considerable amount of chromium, tungsten and a small amount of nickel, molybdenum, silicon, carbon, niobium, tantalum and other alloying elements, and occasionally also containing iron.

Unlike other high-temperature alloys, cobalt-chromium-tungsten alloys are not strengthened by an ordered precipitation phase firmly bonded to the matrix but are composed of austenite fcc matrix that has been solid-solution strengthened and a small number of carbides distributed in the matrix. However, the casting of cobalt-chromium-tungsten superalloys relies to a large extent on carbide strengthening. Pure cobalt crystals have a hexagonal close-packed (hcp) crystal structure below 417°C, which transforms to fcc at higher temperatures. In order to avoid this transformation of cobalt-chromium-tungsten superalloys in use, in fact, all cobalt-chromium-tungsten alloys are alloyed with nickel in order to stabilize the structure from room temperature to melting point temperature. The cobalt-chromium-tungsten alloy has a flat fracture stress-temperature relationship, but it shows better thermal corrosion resistance than other high temperatures above 1000°C. This may be due to the higher chromium content of the alloy.

The thermal stability of carbides in cobalt-chromium-tungsten alloys is better. When the temperature rises, the growth rate of carbide accumulation is slower than the growth rate of the γ phase in the nickel-based alloy, and the temperature of re-dissolving into the matrix is also higher (up to 1100℃). Therefore, when the temperature rises, the cobalt-chromium The strength of tungsten alloys generally declines slowly.

Cobalt-chromium-tungsten alloy has good thermal corrosion resistance. It is generally believed that the reason why cobalt-chromium-tungsten alloy is better than nickel-based alloy in this respect is that the melting point of cobalt sulfide (such as Co-Co4S3 eutectic, 877℃) is higher than that of nickel. The melting point of sulfide (such as Ni-Ni3S2 eutectic 645°C) is high, and the diffusion rate of sulfur in cobalt is much lower than that in nickel. And because most cobalt-chromium-tungsten alloys have higher chromium content than nickel-based alloys, a Cr2O3 protective layer that resists alkali metal sulfates (such as Na2SO4 corrosion) can be formed on the surface of the alloy. However, the oxidation resistance of cobalt-chromium-tungsten alloys is generally lower than that of nickel-based alloys. Feel free to send an inquiry to get the latest price if you would like to buy 3D Printing Alloy CoCrW Powder in bulk.

Composition(percentage by mass)

|

Co |

Cr |

W |

Si |

C |

B |

Mn |

Fe |

|

Bal |

27.62 |

8.79 |

1.5 |

0.99 |

0.56 |

0.5 |

0.5 |

Additional elements less than 1%: N, Nb

Contains no nickel, beryllium or iron

|

category |

Alloy grades and characteristics |

|

Alloy number: |

CoCrMo(W) |

|

Particle size: |

0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm |

|

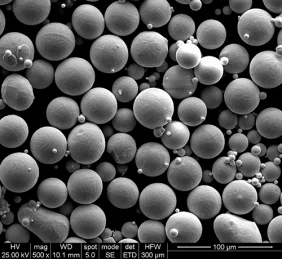

Morphology: |

Spherical or nearly spherical |

|

Appearance: |

Grey |

|

Package: |

Aluminum bag,Vacuum packing |

|

Application: |

3D printing metal powder |

|

Other applications: |

powder metallurgy(PM), injection molding(MIM), spray painting(SP) etc. |

How is 3D Printing Alloy CoCrW Powder produced?

First, smelt the required scrap iron to the melting point, then add the above eight raw materials of cobalt, chromium, tungsten, sulfur, silicon, carbon, aluminum, and copper in sequence, and then lower the temperature to 1150-1200°C for high-temperature solution treatment for 40-60min Secondly, the temperature is lowered to 880-970°C for aging treatment for 2-3 hours, and the cobalt-chromium-tungsten alloy is obtained by annealing again.

Heat treatment

The size and distribution of carbide particles in the cobalt-chromium-tungsten alloy are very sensitive to the casting process. In order to make the cast cobalt-chromium-tungsten alloy parts reach the required endurance strength and thermal fatigue performance, the casting process parameters must be controlled. For cast cobalt-chromium-tungsten alloys, first, perform high-temperature solid solution treatment, usually around 1150℃, so that all primary carbides, including some MC-type carbides, are dissolved into solid solution; then aging treatment is carried out at 870-980℃, So that carbides (the most common is M23C6) precipitation again.

Surfacing

The chromium-tungsten surfacing alloy contains 25-33% chromium, 3-21% tungsten, and 0.7-3.0% carbon. As the carbon content increases, the metallographic structure changes from hypoeutectic austenite + M7C3 eutectic to hyper eutectic M7C3 primary carbide + M7C3 eutectic. The more carbon, the more nascent M7C3, the increased macro-density, and the improved abrasive wear resistance, but the impact resistance, weldability, and machining can still maintain higher hardness and strength at 650°C. This is the difference between this type of alloy. The important features of nickel-based and iron-based alloys.

Abrasion resistance

For cobalt-chromium-tungsten alloys, this feature is related to the fact that the matrix has a certain stacking fault energy and the matrix structure changes from a face-centered cubic to a hexagonal close-packed crystal structure under the effect of stress or temperature. In the cast cobalt-chromium-tungsten alloy, the size of the carbide particles is related to the cooling rate, and the faster the cooling is, the smaller the carbide particles are. In this state, the abrasive wear resistance of the alloy is significantly improved by graphite casting (fine carbide particles), but there is no obvious difference in the wear resistance of adhesive wear, indicating that the coarse carbide is beneficial to improve the resistance Abrasive wearability.

Applications of 3D Printing Alloy CoCrW Powder:

Manufacture of high-strength, high-hardness parts: CoCrW powder has high strength and hardness and can be used to manufacture high-strength, high-hardness parts, such as aircraft engine parts, spacecraft structural components, petrochemical equipment, and other key components. These parts need to work in high temperatures, high pressure, high corrosion, and other harsh environments. CoCrW powder's excellent performance can ensure that these parts of high strength, high hardness, corrosion resistance, and long life.

Manufacture of medical devices: CoCrW powder's high strength, high hardness, and corrosion resistance make it an ideal material for manufacturing medical devices. For example, it can be used to manufacture high-precision, high-stability medical device parts such as surgical instruments, implants, and prosthetics. These devices require high strength and hardness to ensure the reliability and service life of the device, as well as corrosion resistance to ensure the long-term stability and safety of the device.

Manufacture of wear-resistant parts: The hardness and wear resistance of CoCrW powder makes it possible to manufacture a variety of wear-resistant parts and tools, such as high life cutting tools, drills, milling cutters, etc., as well as wear-resistant tools used in excavation, mining, and other fields. These tools and parts need to work in harsh environments, and the excellent properties of CoCrW powders ensure their high wear resistance and long life.

Manufacture of electronic components and semiconductor devices: The high purity and high resistivity of CoCrW powder allows it to be used in the manufacture of high-precision, highly stable electronic components and semiconductor devices. For example, it can manufacture electronic components such as resistors, capacitors, and miniature bearings, as well as packaging and connecting parts for semiconductor devices. These components and devices need to work in harsh environments such as high temperature, high pressure, and high corrosion, and the excellent performance of CoCrW powder ensures their high precision, high stability, and long life.

Manufacture of powder metallurgy products: CoCrW powder has a wide range of applications in powder metallurgy products. High-density, high-performance metal matrix composites, and alloy products can be prepared through the powder pressing and sintering process by utilizing its good pressing and sintering properties. These products can be used in various fields, such as machinery manufacturing, automobile manufacturing, petrochemical industry, etc.

Storage Condition of CoCrW Powder:

Damp reunion will affect CoCrW powder dispersion performance and using effects, therefore, CoCrW powder should be sealed in vacuum packing and stored in cool and dry room, the CoCrW powder can not be exposure to air. In addition, the CoCrW powder should be avoided under stress.

Packing & Shipping of CoCrW powder:

We have many different kinds of packing which depend on the CoCrW powder quantity.

CoCrW powder packing:vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

CoCrW powder shipping: could be shipped out by sea, by air, by express, as soon as possible once payment receipt.

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including boride powder, nitride powder, graphite powder, sulfide powder, 3D printing powder, etc.

If you are looking for high-quality CoCrW Powder, please feel free to contact us and send an inquiry. ([email protected])

3D Printing Alloy CoCrW Powder Properties |

|

| Other Names | Cobalt Chromium Tungsten, Cobalt 6B, Stellite 6B ,Co-Cr-W |

| CAS No. | N/A |

| Compound Formula | CoCrW |

| Molecular Weight | N/A |

| Appearance | Gray metallic solid in various forms (ingot, tubing, pieces, powder) |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | <4.2 g/cm3 |

| Purity | N/A |

| Particle Size | 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | 294.824632 g/mol |

| Monoisotopic Mass | 294.824632 g/mol |

3D Printing Alloy CoCrW Powder Health & Safety Information |

|

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |