What is Hydroxypropyl methylcellulose?

Hydroxypropyl methylcellulose, hydroxypropyl methylcellulose, and HPMC is a non-ionic cellulose ether made from natural polymer material cellulose through a series of chemical processes.

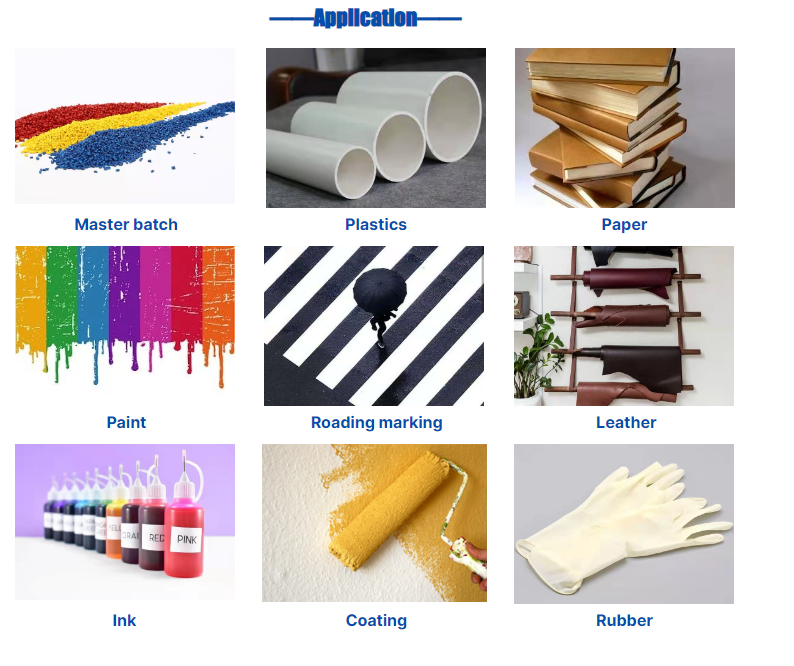

HPMC hydroxypropyl methylcellulose is a white powder that swells into a clear or slightly cloudy colloidal solution in cold water. Hydroxypropyl methylcellulose has the properties of thickening, binding, dispersing, emulsifying, film-forming, suspending, adsorbing, gelling, surface-active, retaining moisture, and protective colloid. Hydroxypropyl methylcellulose can be used in building materials, the paint industry, synthetic resin, the ceramics industry, medicine, textile, agriculture, daily chemical, and other industries.

As a supplier of HPMC Hydroxypropyl methylcellulose CAS No.9004-65-3, TRUNNANO can offer you products with different viscosity and can offer you the best price of HPMC Hydroxypropyl methylcellulose.

Applications of Hydroxypropyl methylcellulose CAS No.9004-65-3 in construction industry:

Cement based plaster

1. Hydroxypropyl methylcellulose HPMC can improve uniformity, make the plastering paste easier to apply, and improve the sag resistance. Enhanced fluidity and pump ability for improved work efficiency.

2. Hydroxypropyl methylcellulose HPMC has high water retention, prolongs the working time of the mortar, improves the working efficiency, and helps the mortar to form high mechanical strength during the solidification period.

3. Hydroxypropyl methylcellulose HPMC controls the infiltration of air, thereby eliminating the micro-cracks of the coating and forming an ideal smooth surface.

Lightweight partition board

1. Hydroxypropyl methylcellulose can enhance the machinability of extruded lightweight boards with bonding strength and lubricity.

2. Hydroxypropyl methylcellulose can improve the wet strength and adhesion of the sheet after extrusion.

Gypsum plaster and gypsum products

1. HPMC Hydroxypropyl methylcellulose can improve the uniformity, make the plastering paste easier to apply, and at the same time, improve the sag resistance and enhance the fluidity and pumpability. Thereby improving work efficiency.

2. HPMC Hydroxypropyl methylcellulose can improve the water retention of gypsum, prolong the working time of the mortar, and produce high mechanical strength during solidification.

3. HPMC Hydroxypropyl methylcellulose can form a high-quality surface coating by controlling the consistency of the mortar.

Masonry mortar

1. HPMC Hydroxypropyl methylcellulose can enhance the adhesion with the masonry surface and can enhance the water retention so that the strength of the mortar can be improved.

2. HPMC Hydroxypropyl methylcellulose can improve lubricity and plasticity to improve construction performance using cellulose ether-enhanced mortar, which is easier to apply, saves time, and improves cost-effectiveness.

3. HPMC Hydroxypropyl methylcellulose has special high water retention models, suitable for high water absorption bricks.

Sheet joint filler

1. HPMC Hydroxypropyl methylcellulose has excellent water retention, which can prolong the cooling time and improve work efficiency. High lubricity makes application easier and smoother.

2. HPMC Hydroxypropyl methylcellulose can improve shrinkage resistance and crack resistance and improve surface quality.

3. HPMC Hydroxypropyl methylcellulose has a smooth and uniform texture and makes the bonding surface stronger.

Tile adhesive

1. can make the dry blending ingredients easy to mix without any agglomeration, thus saving working time. Improves workability and reduces costs due to faster and more efficient applications.

2. HPMC Hydroxypropyl methylcellulose can improve the tiling efficiency by prolonging the cooling time to achieve a sticky effect.

3. HPMC Hydroxypropyl methylcellulose can provide specially developed models with high slip resistance.

Water-Based Paints and Paint Strippers

1. HPMC Hydroxypropyl methylcellulose can prolong the shelf life by preventing solid precipitation. Compatibility with other components and high biological stability.

2. HPMC Hydroxypropyl methylcellulose can dissolve quickly without lumps, which helps to simplify the mixing process. Cold water dispersion version for faster and easier mixing without clumps.

3. HPMC Hydroxypropyl methylcellulose produces favorable flow properties, including low spatter and good leveling, which ensures excellent surface finish and prevents paint sag.

4. HPMC Hydroxypropyl methylcellulose enhances the viscosity of water-based paint remover and organic solvent paint remover so that the paint remover will not flow out of the workpiece surface.

Self-leveling floor material

1. HPMC Hydroxypropyl methylcellulose provides viscosity and can be used as an anti-precipitation aid.

2. HPMC Hydroxypropyl methylcellulose enhances fluidity and pum pability, thereby improving the efficiency of paving.

3. HPMC Hydroxypropyl methylcellulose controls water retention, thereby greatly reducing cracking and shrinkage.

Packaging and storage of HPMC Hydroxypropyl methylcellulose

This product is packaged in a film-coated plastic woven bag with a net weight of 25kg per piece.

Avoid rain during storage and transportation.

Fire and moisture-proof.