By TRUNNANO | 07 April 2024 | 0 Comments

What is Lithium silicate aqueous solution?

What is a lithium silicate aqueous solution?

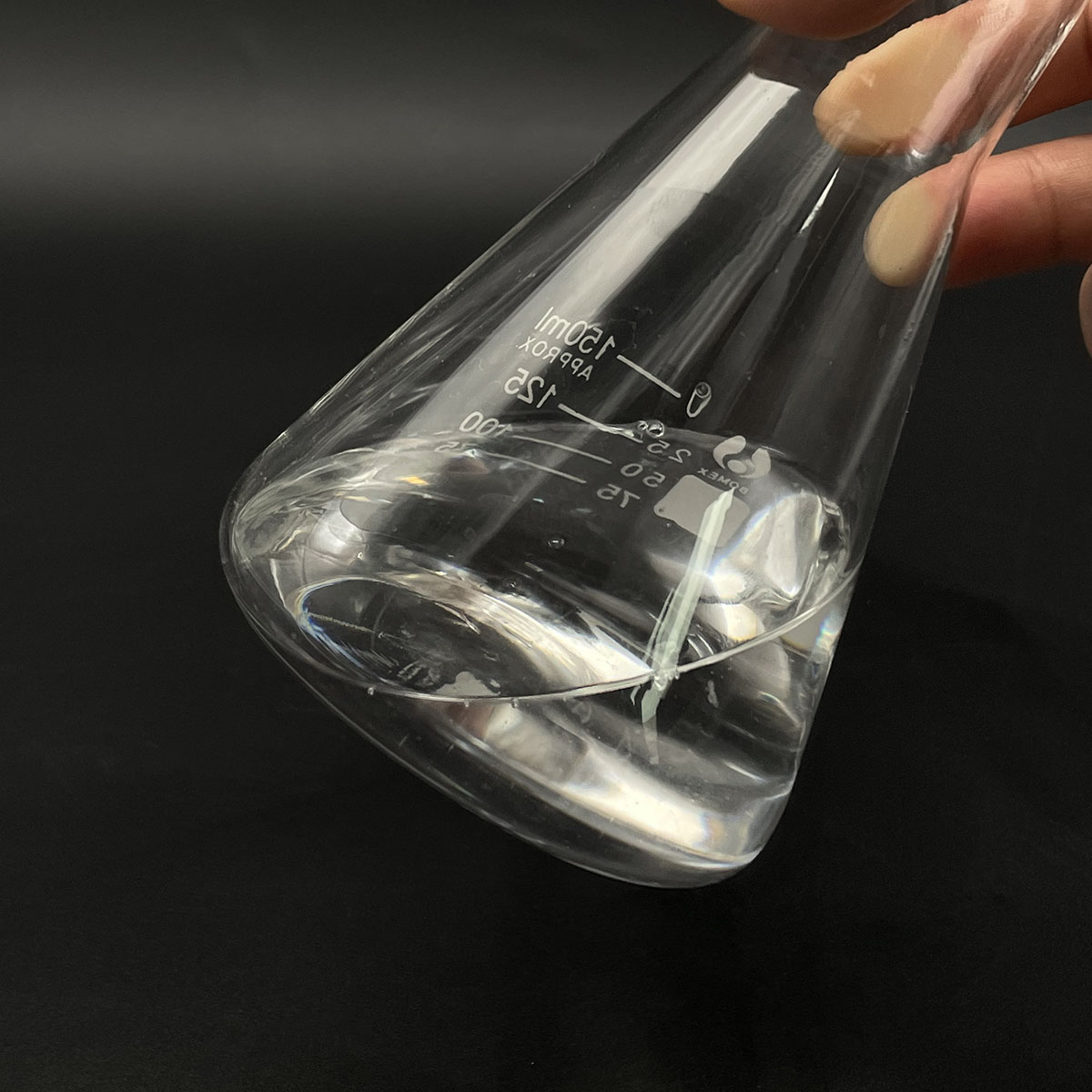

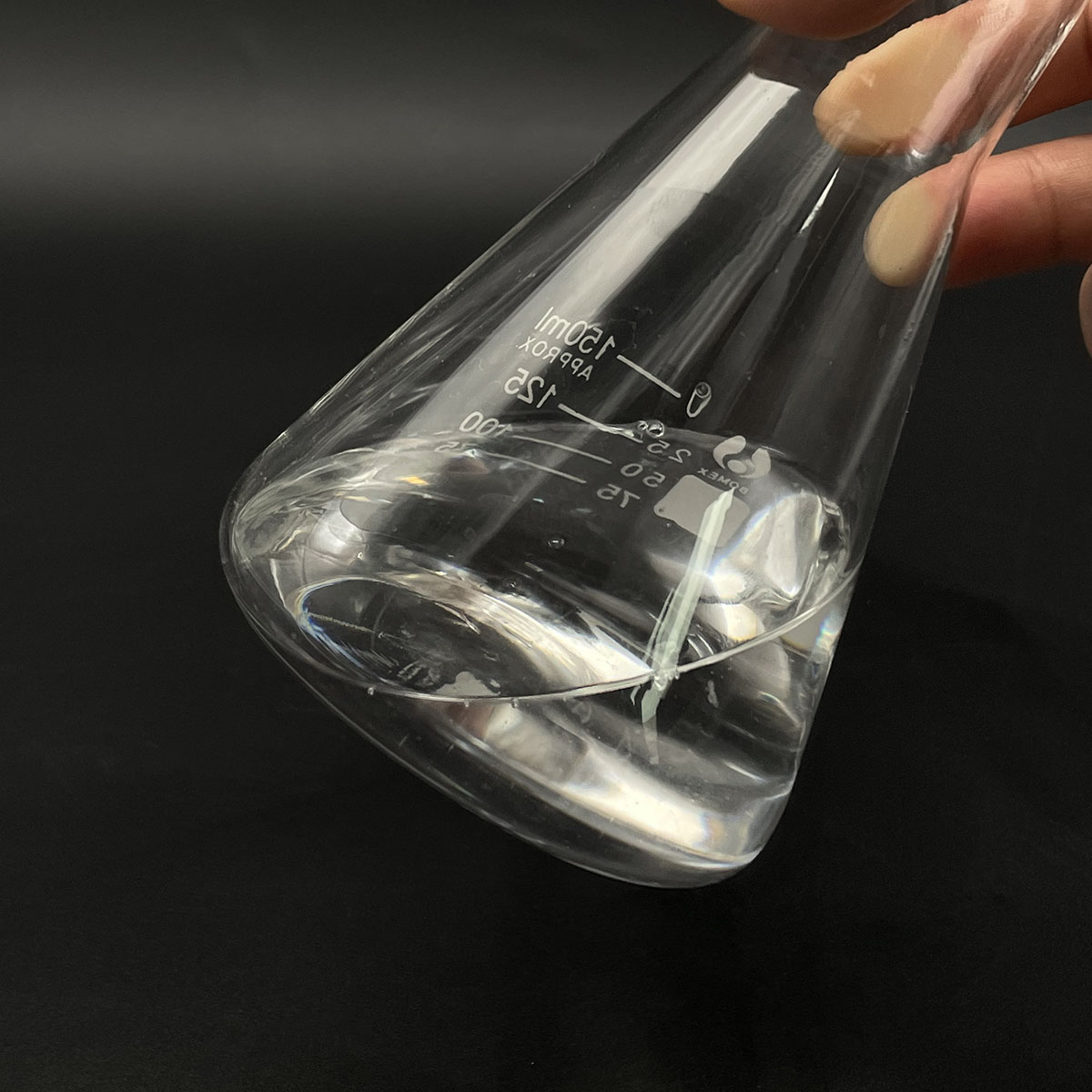

Lithium silicate aqueous solution is characterized by good chemical stability, high transparency, high viscosity, good water resistance and environmental friendliness, etc. It is widely used in the fields of construction, coating, adhesive, battery, glass ceramics, and chemical industry. With the progress of science and technology and the development of industrial production, the application fields of lithium silicate aqueous solution will continue to expand, and its role in various fields will be more prominent. Therefore, the in-depth study and application of lithium silicate aqueous solution has important practical significance and broad market prospects. What is Lithium silicate?

What is Lithium silicate?

Lithium silicate is a compound formed by the structure of lithium metal and silicate root, and its trade name is lithium water glass. Most lithium silicate is prepared by the lithium hydroxide method; that is, sodium silicate reacts with sulfuric acid to produce hydrated silicic acid and sodium sulfate and then takes hydrated silicic acid to react with lithium hydroxide to produce lithium silicate and water. Lithium silicate is an odorless, tasteless, transparent liquid with a pH value of about 11, alkaline, soluble in water and alkaline solutions, but insoluble in alcohols and organic solvents.

Lithium silicate has some unique characteristics, such as the ability to free gel with acid action and good self-drying properties. When the water in the solution evaporates, it can generate a dry film that is insoluble in water, and this water irreversibility makes the waterproof effect of lithium silicate particularly obvious.

The preparation method of lithium silicate

There are various methods for the preparation of lithium silicate, of which the more traditional is the solid-phase method. This method generally uses Li-OH-H2O, Li2CO3, and SiO2 as raw materials and lithium silicate powder is obtained by mixing ball milling and forging at high temperatures. Although the solid-phase method of preparing lithium silicate has the advantages of high powdering efficiency, low cost, and simple preparation, it also has the disadvantages of low efficiency, high energy consumption, and coarse powder particles.

Another method for preparing lithium silicate is the sol-gel method, which is a commonly used liquid phase method. This method allows the reactants to be uniformly mixed, the reaction temperature is low, and the reaction is easy to carry out. When preparing lithium silicate powder, choosing the right raw material is crucial.

Features of lithium silicate aqueous solution

Chemical stability: Lithium silicate aqueous solution has good chemical stability, and it is not easy to react with other substances. This makes the lithium silicate aqueous solution, in the storage and use process, able to maintain its stability for a longer period of time, reducing the performance changes caused by chemical reactions.

High transparency: Lithium silicate aqueous solutions are highly transparent, which is conducive to observing their changes during use. Increased transparency also allows lithium silicate aqueous solutions to better control the reaction process when preparing other materials.

High Viscosity: Lithium silicate aqueous solution has a high viscosity, which makes it uniquely advantageous in certain applications. For example, in coatings and adhesives, a high-viscosity lithium silicate aqueous solution can better adhere to the substrate, improving the product's adhesion and durability.

Good water resistance: Lithium silicate aqueous solution has good water resistance and maintains good performance even in humid environments. This makes lithium silicate aqueous solution has a wide range of application prospects in the fields of construction and coating.

Environmental protection: Lithium silicate aqueous solution is non-toxic and harmless and will not pollute the environment. At the same time, its production process is relatively simple and low energy-consuming, in line with environmental requirements.

Applications of lithium silicate aqueous solution

Construction field

In the field of construction, lithium silicate aqueous solution, as an excellent waterproof and moisture-proof material, is widely used in the waterproof treatment of basements, bathrooms, kitchens and other humid environments. Its excellent water resistance and adhesion enable lithium silicate aqueous solution to effectively prevent moisture penetration and protect the safety and stability of the building structure. In addition, lithium silicate aqueous solution can be used as an additive for architectural coatings to improve the durability and adhesion of coatings.

Coating field

In the field of coatings, lithium silicate aqueous solution is used as a main ingredient or additive in coatings to improve the performance of coatings. Lithium silicate aqueous solution improves the adhesion, weathering, and water resistance of the coatings so that the coatings can maintain good performance under harsh environments. In addition, lithium silicate aqueous solution can also be used as a raw material for fireproof coatings to improve the fireproof performance of coatings.

Adhesive field

Lithium silicate aqueous solution is also widely used in the field of adhesives. Due to its high viscosity and good adhesion, it can be used as the main ingredient in all kinds of adhesives, sealants, and caulks. These products have excellent adhesion and durability and can meet the needs of different fields.

Battery field

In the battery field, lithium silicate aqueous solution is used as an electrolyte or additive to improve battery performance and safety. Its good ionic conductivity can improve the battery's charging and discharging efficiency, and its chemical stability can effectively prevent safety accidents such as short circuits or explosions inside the battery.

Glass-ceramics field

In the field of glass ceramics, lithium silicate aqueous solution can be used as an additive for glass ceramics to improve its physical properties and chemical stability. The addition of lithium silicate aqueous solution can improve the heat resistance, corrosion resistance, and mechanical strength of glass ceramics so that it can still maintain good performance in high temperature, high pressure, or chemical corrosion and other harsh environments.

Chemical field

In the chemical field, lithium silicate aqueous solution can be used as a catalyst, stabilizer, or analytical reagent. Its unique chemical properties make lithium silicate an aqueous solution that can play an important role in the chemical reaction to promote the reaction; at the same time, it can also be used as a stabilizer for some chemical reactions to prevent instability in the reaction process. In addition, lithium silicate aqueous solution is also widely used in analytical chemistry and can be used to determine the content of certain substances or qualitative analysis.

Liquid Lithium Silicate lithium silicate aqueous solution supplier

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and nanomaterials, lithium silicate aqueous solution including boride powder, nitride powder, graphite powder, sulfide powder, 3D printing powder, etc.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality Liquid Lithium Silicate, please feel free to contact us [email protected] to send an inquiry.

Lithium silicate aqueous solution is characterized by good chemical stability, high transparency, high viscosity, good water resistance and environmental friendliness, etc. It is widely used in the fields of construction, coating, adhesive, battery, glass ceramics, and chemical industry. With the progress of science and technology and the development of industrial production, the application fields of lithium silicate aqueous solution will continue to expand, and its role in various fields will be more prominent. Therefore, the in-depth study and application of lithium silicate aqueous solution has important practical significance and broad market prospects.

Lithium silicate is a compound formed by the structure of lithium metal and silicate root, and its trade name is lithium water glass. Most lithium silicate is prepared by the lithium hydroxide method; that is, sodium silicate reacts with sulfuric acid to produce hydrated silicic acid and sodium sulfate and then takes hydrated silicic acid to react with lithium hydroxide to produce lithium silicate and water. Lithium silicate is an odorless, tasteless, transparent liquid with a pH value of about 11, alkaline, soluble in water and alkaline solutions, but insoluble in alcohols and organic solvents.

Lithium silicate has some unique characteristics, such as the ability to free gel with acid action and good self-drying properties. When the water in the solution evaporates, it can generate a dry film that is insoluble in water, and this water irreversibility makes the waterproof effect of lithium silicate particularly obvious.

The preparation method of lithium silicate

There are various methods for the preparation of lithium silicate, of which the more traditional is the solid-phase method. This method generally uses Li-OH-H2O, Li2CO3, and SiO2 as raw materials and lithium silicate powder is obtained by mixing ball milling and forging at high temperatures. Although the solid-phase method of preparing lithium silicate has the advantages of high powdering efficiency, low cost, and simple preparation, it also has the disadvantages of low efficiency, high energy consumption, and coarse powder particles.

Another method for preparing lithium silicate is the sol-gel method, which is a commonly used liquid phase method. This method allows the reactants to be uniformly mixed, the reaction temperature is low, and the reaction is easy to carry out. When preparing lithium silicate powder, choosing the right raw material is crucial.

Features of lithium silicate aqueous solution

Chemical stability: Lithium silicate aqueous solution has good chemical stability, and it is not easy to react with other substances. This makes the lithium silicate aqueous solution, in the storage and use process, able to maintain its stability for a longer period of time, reducing the performance changes caused by chemical reactions.

High transparency: Lithium silicate aqueous solutions are highly transparent, which is conducive to observing their changes during use. Increased transparency also allows lithium silicate aqueous solutions to better control the reaction process when preparing other materials.

High Viscosity: Lithium silicate aqueous solution has a high viscosity, which makes it uniquely advantageous in certain applications. For example, in coatings and adhesives, a high-viscosity lithium silicate aqueous solution can better adhere to the substrate, improving the product's adhesion and durability.

Good water resistance: Lithium silicate aqueous solution has good water resistance and maintains good performance even in humid environments. This makes lithium silicate aqueous solution has a wide range of application prospects in the fields of construction and coating.

Environmental protection: Lithium silicate aqueous solution is non-toxic and harmless and will not pollute the environment. At the same time, its production process is relatively simple and low energy-consuming, in line with environmental requirements.

Applications of lithium silicate aqueous solution

Construction field

In the field of construction, lithium silicate aqueous solution, as an excellent waterproof and moisture-proof material, is widely used in the waterproof treatment of basements, bathrooms, kitchens and other humid environments. Its excellent water resistance and adhesion enable lithium silicate aqueous solution to effectively prevent moisture penetration and protect the safety and stability of the building structure. In addition, lithium silicate aqueous solution can be used as an additive for architectural coatings to improve the durability and adhesion of coatings.

Coating field

In the field of coatings, lithium silicate aqueous solution is used as a main ingredient or additive in coatings to improve the performance of coatings. Lithium silicate aqueous solution improves the adhesion, weathering, and water resistance of the coatings so that the coatings can maintain good performance under harsh environments. In addition, lithium silicate aqueous solution can also be used as a raw material for fireproof coatings to improve the fireproof performance of coatings.

Adhesive field

Lithium silicate aqueous solution is also widely used in the field of adhesives. Due to its high viscosity and good adhesion, it can be used as the main ingredient in all kinds of adhesives, sealants, and caulks. These products have excellent adhesion and durability and can meet the needs of different fields.

Battery field

In the battery field, lithium silicate aqueous solution is used as an electrolyte or additive to improve battery performance and safety. Its good ionic conductivity can improve the battery's charging and discharging efficiency, and its chemical stability can effectively prevent safety accidents such as short circuits or explosions inside the battery.

Glass-ceramics field

In the field of glass ceramics, lithium silicate aqueous solution can be used as an additive for glass ceramics to improve its physical properties and chemical stability. The addition of lithium silicate aqueous solution can improve the heat resistance, corrosion resistance, and mechanical strength of glass ceramics so that it can still maintain good performance in high temperature, high pressure, or chemical corrosion and other harsh environments.

Chemical field

In the chemical field, lithium silicate aqueous solution can be used as a catalyst, stabilizer, or analytical reagent. Its unique chemical properties make lithium silicate an aqueous solution that can play an important role in the chemical reaction to promote the reaction; at the same time, it can also be used as a stabilizer for some chemical reactions to prevent instability in the reaction process. In addition, lithium silicate aqueous solution is also widely used in analytical chemistry and can be used to determine the content of certain substances or qualitative analysis.

Liquid Lithium Silicate lithium silicate aqueous solution supplier

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and nanomaterials, lithium silicate aqueous solution including boride powder, nitride powder, graphite powder, sulfide powder, 3D printing powder, etc.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality Liquid Lithium Silicate, please feel free to contact us [email protected] to send an inquiry.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- This article lets you find out exactly what aerogel is

- What is graphene aerogel?

- What is Cadmium telluride CdTe and CdTe solar cell?

- Four types of surfactants and their differences and applications

- What is the explosive welding cladding of metal plates?

- What is EBS Ethylene Bis Stearamide?

- An article lets you understand the characteristics and applications of sodium silicate

- Advantages of graphite anode for lithium-ion battery

- What is Spherical Quartz Powder?

- What is sodium silicate?

CATEGORIES