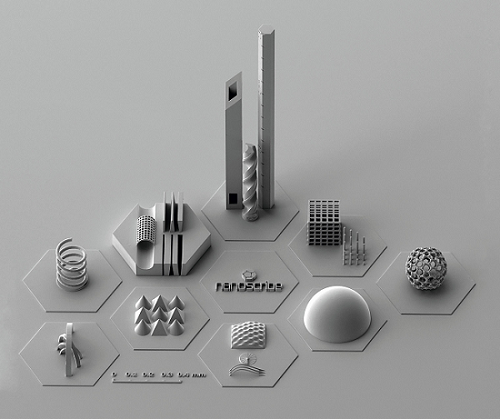

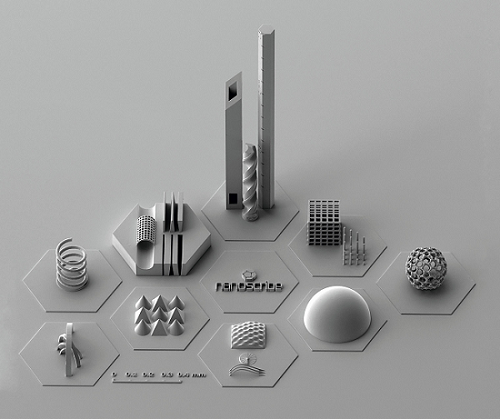

As part of the 3D printing metamaterial series, this article will continue to explore nano 3D printing technology, which is dedicated to printing individual nanoscale biomedical and electronic devices, which are usually used for research purposes. At present, researchers are studying how to achieve macroscopic physical property changes by printing microscopic objects.

A new project to explore these possibilities was developed by Lawrence Livermore National Laboratory (LLNL), who used a projection microlithography technique (PμSL) to create a plan capable of supporting 10,000 times its weight. As with most metamaterials, we explored in this series, the key to this far-reaching power lies in the structure's geometry.

To fabricate the microlattice structure, the LLNL team used a system to project the ultraviolet light of the LED onto the micromirror, which reflected the light through a series of optical elements, reduced the size of the beam, and projected it to photopolymerization On the slot. The researchers tested various lattice geometries and found that the rigidity and strength of the microcrystalline structures depend on their density.

Although polymer resin is their primary material, the research team can create metal and ceramic micro lattice structures by adding metal and ceramic materials to the gum and then burning off the polymer with thermal energy. The resulting object is more durable while still maintaining a very lightweight.

Based on this research, LLNL expands it in various ways. For example, LLNL applies this technology to the study of how to use metamaterials and 3D printing to optimize the design of helmets. The laboratory compared traditional elastomer foam materials to metamaterials composed of 3D printed polymer thin layers, and determined that 3D printed polymers age slower than conventional elastomers; The elastomers age faster. Other studies have also explored copper-polymer composites that shrink when heated.

Cheng Zhu, a researcher at Lawrence Livermore National Laboratory and Wen Chen, a former postdoctoral fellow in the laboratory, created an ink composed of gold and silver particles. After printing, the 3D parts were heated to condense the particles into a gold and silver alloy. These parts are placed in a chemical bath to remove silver (this process is called "dealloying") to form porous gold.

However, even these nanoscale systems can be developed in a more refined direction. The Max Planck Institute of Light Sciences has developed a method described as a prelude to atomic-level printing. This technology couples light with a single atom or a single nanoparticle in a parabolic mirror, thereby achieving light wave clipping.

Then, the space-time distribution of light and the polarization vector or oscillation direction of the electric field can be focused on the object at a smaller scale than the wavelength of the light itself. The team has used this method to create nanostructures with unique characteristics and believes that it is possible to trap a single atom with a laser beam to build a structure with strange atomic accuracy.

Nano and microscale 3D printing powder may help handle the micro-world of cells, but most of this research is for subsequent application at the macro scale. Therefore, various scientific teams are working hard to produce these nanoscale objects and then deploy them outside the laboratory. Researchers at Virginia Tech are studying how the behavior of structured materials changes when they are magnified by seven orders of magnitude. Beyond two-photon polymerization, the team created tens of centimeters-sized metal parts composed of nanoscale hollow tubes, proving that their tensile elasticity is 400% higher than similar products without structured nano-features.

LLNL itself has been committed to combining nanoscale printing with traditional stereolithography through large-area projection microscopic stereolithography, thereby expanding the scale of nanoimprinting. Its inventor Bryan Moran described it this way: "The LAPμSL system is similar in concept to building a mosaic and then combining it into a larger picture. Each tile has a lot of details, and they form a movie together, And in turn, there will be more details. "This is a new tool that can make more significant size parts quickly, and it is more useful. "

TRUNNANO (Luoyang Trunnano Tech Co., Ltd ) is a professional 3D Printing Inconel Alloy In625 Powder manufacturer with over 12 years experience in chemical products research and development. If you are looking for high quality 3D Printing Inconel Alloy In625 Powder, please feel free to contact us and send an inquiry.