By TRUNNANO | 30 May 2023 | 0 Comments

An alloy powder for making superelastic and shape memory products

Nitinol powder enables the manufacture of the shape memory alloy Nitinol, which can return to its original shape after deformation. Memory alloys, used in industries ranging from consumer appliances to automotive, aerospace, and medical, have gained a strong foothold because they offer designers the incredible flexibility to replace traditional materials. In medical devices, Nitinol is popular for its biocompatibility and superelasticity.

Why does Nitinol have a shape memory effect?

Most nickel-titanium materials are simple alloys of nickel and titanium, approximately 50 atomic percent each (approximately 55 percent nickel by weight). However, small adjustments in the ratio of the two elements can make a big difference in the properties of Nitinol, especially its transition temperature, the temperature at which the alloy's crystal structure changes from austenite to martensite or vice versa. The shape memory effect occurs when a material changes crystal form when cooled or heated to its characteristic transition temperature. This change in the crystal structure in Nitinol is from an ordered cubic phase above its transformation temperature (austenite) to a monoclinic phase below its transformation temperature (martensite).

Nitinol alloys are able to get very hard when working with cold temperatures such as rolling or drawing. If the alloy isn't properly annealed after a particular amount of cold-working then the strength will increase until it is at the breaking point after further deformation and then failure is likely to occur. When the product has annealed and treated properly, it will give it the highest possible quality of shape memory and superelasticity whilst keeping enough of the cold-working effects to withstand the deformation that is permanent during cycling.

What are the potential applications of Nitinol?

A variety of outstanding characteristics of the nickel-titanium alloy makes it a popular choice for aerospace manufacturing, automotive industry, medical equipment as well as other fields.

Aerospace

The application of nickel-titanium alloys in aerospace mainly includes pipe joints on aircraft, spacecraft antennas, fasteners, connecting parts, electrical connections, and electromechanical actuators.

Automobile industry

Nickel-titanium alloys are often used in automobile engine heat-resistant fan clutches, exhaust automatic adjustment nozzles, diesel engine radiator hole automatic switches, and shape memory springs for jet engine oil filters.

Medical equipment

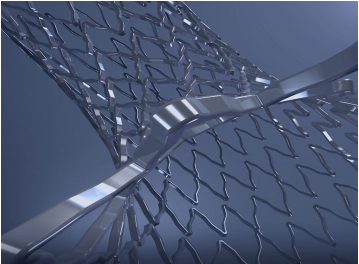

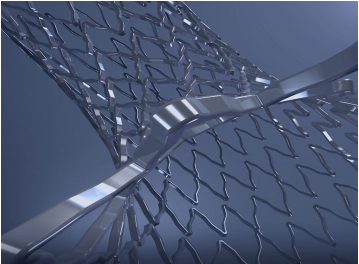

Nickel-titanium alloys have been successfully used in orthodontics, surgical orthodontics, plastic surgery, and minimally invasive cardiovascular interventional therapy. There are surgical sutures, cerebral aneurysm clips, contraceptive rings, artificial hearts, and micropumps for artificial kidneys that have entered medical clinical trials. Nitinol is also used to make stents, guide wires, stone retrieval baskets, filters, needles, dental files, and other surgical instruments.

Civilian products

Civilian products include ultra-elastic spectacle frames, mobile phone antennas, women's corset brackets, high-elastic and high-tenacity fishing threads, earphone headgear, etc.

Quality Nitinol Powder supplier

TRUNNANO (aka Luoyang Tongrun Nano Technology Co., Ltd.) is a reputable global chemical material manufacturer and supplier with more than 12 years ' experience in providing the highest quality of chemical products and nanomaterials. Our company has created an array of powder materials. We offer OEM services. If you're in search of Nitinol powder Please get in touch with us. You can click on the desired product to contact us with an inquiry.

Most nickel-titanium materials are simple alloys of nickel and titanium, approximately 50 atomic percent each (approximately 55 percent nickel by weight). However, small adjustments in the ratio of the two elements can make a big difference in the properties of Nitinol, especially its transition temperature, the temperature at which the alloy's crystal structure changes from austenite to martensite or vice versa. The shape memory effect occurs when a material changes crystal form when cooled or heated to its characteristic transition temperature. This change in the crystal structure in Nitinol is from an ordered cubic phase above its transformation temperature (austenite) to a monoclinic phase below its transformation temperature (martensite).

Nitinol alloys are able to get very hard when working with cold temperatures such as rolling or drawing. If the alloy isn't properly annealed after a particular amount of cold-working then the strength will increase until it is at the breaking point after further deformation and then failure is likely to occur. When the product has annealed and treated properly, it will give it the highest possible quality of shape memory and superelasticity whilst keeping enough of the cold-working effects to withstand the deformation that is permanent during cycling.

What are the potential applications of Nitinol?

A variety of outstanding characteristics of the nickel-titanium alloy makes it a popular choice for aerospace manufacturing, automotive industry, medical equipment as well as other fields.

Aerospace

The application of nickel-titanium alloys in aerospace mainly includes pipe joints on aircraft, spacecraft antennas, fasteners, connecting parts, electrical connections, and electromechanical actuators.

Automobile industry

Nickel-titanium alloys are often used in automobile engine heat-resistant fan clutches, exhaust automatic adjustment nozzles, diesel engine radiator hole automatic switches, and shape memory springs for jet engine oil filters.

Medical equipment

Nickel-titanium alloys have been successfully used in orthodontics, surgical orthodontics, plastic surgery, and minimally invasive cardiovascular interventional therapy. There are surgical sutures, cerebral aneurysm clips, contraceptive rings, artificial hearts, and micropumps for artificial kidneys that have entered medical clinical trials. Nitinol is also used to make stents, guide wires, stone retrieval baskets, filters, needles, dental files, and other surgical instruments.

Civilian products

Civilian products include ultra-elastic spectacle frames, mobile phone antennas, women's corset brackets, high-elastic and high-tenacity fishing threads, earphone headgear, etc.

Quality Nitinol Powder supplier

TRUNNANO (aka Luoyang Tongrun Nano Technology Co., Ltd.) is a reputable global chemical material manufacturer and supplier with more than 12 years ' experience in providing the highest quality of chemical products and nanomaterials. Our company has created an array of powder materials. We offer OEM services. If you're in search of Nitinol powder Please get in touch with us. You can click on the desired product to contact us with an inquiry.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- What is graphene aerogel?

- What is Cadmium telluride CdTe and CdTe solar cell?

- Four types of surfactants and their differences and applications

- What is the explosive welding cladding of metal plates?

- What is EBS Ethylene Bis Stearamide?

- An article lets you understand the characteristics and applications of sodium silicate

- Advantages of graphite anode for lithium-ion battery

- What is Spherical Quartz Powder?

- What is sodium silicate?

- Characteristics and Application of Spherical Alumina

CATEGORIES