By Dr.Qian from Guizhou University of Finance and Eco | 16 July 2020 | 0 Comments

Overall reviews of silver powder

What is silver and silver powder?

Silver (Argentum), which is one of the transition metals. It’s chemical symbol is Ag. Silver exists in nature, but most of it is in the form of compound in silver ore. The physical and chemical properties of silver are relatively stable, with good thermal conductivity and electrical conductivity. Its high reflectivity, up to 99%. It has many important uses.

Silver powder belongs to the kind of silver, which is used to make conductive plastics, conductive coatings and conductive adhesives. The flake silver powder is widely used in the electronic components such as carbon film potentiometer end, film switch and filter. Many ways about the preparation and synthesis of silver you should know

Many ways about the preparation and synthesis of silver you should know

The specific steps are belows:

The specific steps are belows:

A:Preparation of silver salt solution: dissolve silver nitrate in deionized water to prepare silver nitrate solution with a concentration of 0.8 ~ 1.2mol/L, and then put it into the reaction kettle for use; B: Preparation of silver powder: heat the silver nitrate solution to 35 ~ 40℃, and then add the alkaline material solution; then continue to heat to 48 ~ 52℃, and then add fully dissolved gelatin solution; continue heating to 58 ~ 61℃, and add reducing agent; until the chemical reaction in the silver nitrate solution is complete, the initial product of silver powder is obtained;C:Silver powder cleaning: add deionized water to the reaction kettle, clean and dry the finished silver powder, and obtain the finished silver powder.  In addition to high purity and good dispersion, the shape of silver powder in electronic industry also has special requirements. Different shapes of powder in the same use environment, its performance will have a great difference. Flake silver powder is widely used in carbon film potentiometer, capacitor, film switch and semiconductor chip bonding. Flake silver powder is an important part of electrode paste. Flake silver powder refers to flake powder with one-dimensional thickness less than 100 nm.

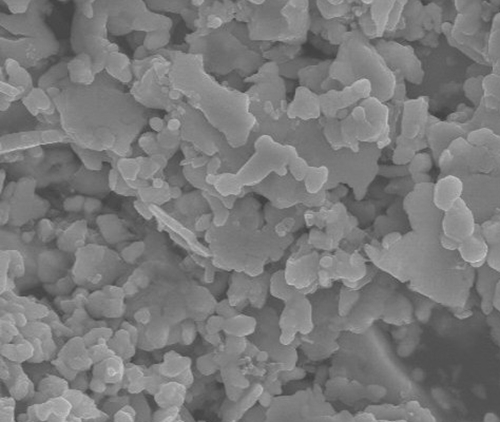

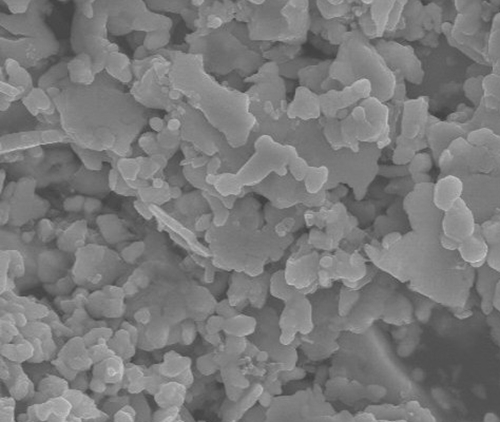

In addition to high purity and good dispersion, the shape of silver powder in electronic industry also has special requirements. Different shapes of powder in the same use environment, its performance will have a great difference. Flake silver powder is widely used in carbon film potentiometer, capacitor, film switch and semiconductor chip bonding. Flake silver powder is an important part of electrode paste. Flake silver powder refers to flake powder with one-dimensional thickness less than 100 nm.

Compared with spherical silver powder, flake silver powder has the following advantages:

1, Its conductive performance is good. The shape of silver particles is in close relationship with conductivity. Flake silver powders are arranged in chip structure, which has good liquidity. Because the contact is surface contact between the flake silver powder particles or line contact and the contact area of point contact is larger than the spherical silver powders, its resistance is relatively low, conductive performance is better.

2, It has high credibility. Because the spherical powder has the smallest activity of specific surface area and high surface energy, it has high degree of oxidation and oxidation tendency. And the specific surface area of the flake silver powders is opposite bigger than the low surface energy, it has low degree of oxidation and oxidation tendency. In addition, flake silver powder wide scope of torsion degrees and flexural crack stretching characteristics improve the reliability of electronic components.

3, It can save silver powder. With the same quality of flake silver powder and other shapes of silver powder coating, coating area of flake silver powder is largest; Therefore, using flake silver powder, on the one hand, can save the amount of silver powder, on the other hand, can reduce the thickness of coating, which is conducive to the miniaturization of electronic components. Applications of silver

Applications of silver

1.The positive silver paste plays a crucial role in solar cells, and the silver powder plays a leading role in the positive silver paste. Silver powder is the conductive phase of positive silver paste, and its mass ratio can reach 80-92%, which has a great influence on the rheological property and printing property of paste, and plays a decisive role in the photoelectric conversion efficiency of solar cells. Current positive silver pulp with silver powder particle size distribution in 1 ~ 2 microns, usually it is easy to appear soft reunion phenomenon. It needs surface treatment by mechanical or chemical reagents. The surface treatment of aluminium powder can increase its wettability, affinity, and carrier increase printing performance and improve the flowing property of the thick liquid material, so the silver powder surface modification for solar battery positive silver pulp with excellent properties is very important.

2.Silver powder paint can not only resist corrosion and water, but also resist high temperature and rust. Silver powder paint will be dry in a moment after being used, which has a strong adhesion. So it is widely used in some heating equipment, vehicles, metal pipes, and some need to be anticorrosive metal surface and so on

3.Sterling silver application

Sterling silver is a beautiful silver-white metal with excellent ductility, electrical and thermal conductivity. Silver is often used to make highly sensitive physical instrument components. It is used to make a large number of contact points in various automation devices, rockets, submarines, computers, nuclear devices and communication systems. During use, each contact point needs to work millions of times. It must be wear-resistant, reliable and able to withstand strict working requirements. Silver can fully meet all kinds of requirements. If rare earth elements are added to silver, the properties are even better. The life of a contact point made with rare-earth silver can be extended several times.

The most important compound of silver is silver nitrate. In medicine, aqueous solution of silver nitrate is commonly used as eye drops. 4.Electrical and electronic materials

4.Electrical and electronic materials

Electrical and electronic equipment is the industry with the largest amount of silver, its use is divided into electrical contact materials, composite materials and welding materials. Silver and silver-based electrical contact materials can be classified into pure silver, silver alloy, silver-oxide and sintered alloy. Worldwide annual output of silver and silver-based contact materials is about 2,900 ~ 3,000 tons. Composite materials are prepared by composite technology, including silver alloy composite materials and silver matrix composite materials. From the perspective of silver saving technology, silver composite materials are a new kind of materials with great development prospects. Silver welding materials include pure silver solder, silver, copper solder, etc.

5.Light-sensitive materials

Silver halide photosensitive materials are one of the fields with the largest amount of silver. At present, photographic film, photographic paper, X-ray film, fluorescence information documentary, electron microscope photographic film and printing film are the most important photographic materials. Due to the development of electronic imaging and digital imaging technology, the amount of silver halide photosensitive material has been reduced, but the application of silver halide photosensitive material is still irreplaceable in some aspects, and there is still a large market space.

6.Chemical materials

Silver has two main applications in this regard, one as a catalyst, such as widely used in REDOX and polymerization reactions, for the treatment of sulphide containing industrial waste gas.The other is used in electronic electroplating industrial preparations, such as silver slurry, potassium cyanide, etc.

7.Craft ornaments

Silver has attractive white luster, high chemical stability and collection value, favored by people, so it has the reputation of "women's metal", which is widely used as jewelry, ornaments, silverware, tableware, congratulatory gifts, MEDALS and commemorative COINS. Silver jewelry has a broad market in developing countries, and silver tableware is welcomed by families. The silver commemorative coin is beautifully designed, with a small circulation, and has the function of maintaining and increasing value, which is highly appreciated by coin collectors and coin investors.  8.In living organisms

8.In living organisms

Silver ions and compounds are toxic to some bacteria, viruses, algae and fungi, but are almost completely harmless to humans. This bactericidal effect of silver allows it to kill living organisms in vitro. However, testing and standardizing silver products is difficult.

Silver is being used in new applications as a versatile antimicrobial agent. One is to dissolve silver nitrate in alginate to prevent infection of wounds, especially burn wounds. Silver-coated glass have good antibacterial properties. In addition, the food and drug administration (FDA) has approved the use of a silver-coated airway that studies have shown to be effective in reducing airway pneumonia.

Silver is not toxic to the human body, but long-term exposure to silver metals and non-toxic silver compounds can also cause silver deposit. Because the body pigment changes, the skin surface will appear gray-blue. Although not toxic, it can still affect the appearance.

TRUNNANO (Luoyang Trunnano Tech Co., Ltd ) is a professional Silver powder manufacturer with over 12 years experience in chemical products research and development. If you are looking for high quality Silver powder, please feel free to contact us and send an inquiry.

Silver (Argentum), which is one of the transition metals. It’s chemical symbol is Ag. Silver exists in nature, but most of it is in the form of compound in silver ore. The physical and chemical properties of silver are relatively stable, with good thermal conductivity and electrical conductivity. Its high reflectivity, up to 99%. It has many important uses.

Silver powder belongs to the kind of silver, which is used to make conductive plastics, conductive coatings and conductive adhesives. The flake silver powder is widely used in the electronic components such as carbon film potentiometer end, film switch and filter.

- A preparation method of common silver powder

A:Preparation of silver salt solution: dissolve silver nitrate in deionized water to prepare silver nitrate solution with a concentration of 0.8 ~ 1.2mol/L, and then put it into the reaction kettle for use; B: Preparation of silver powder: heat the silver nitrate solution to 35 ~ 40℃, and then add the alkaline material solution; then continue to heat to 48 ~ 52℃, and then add fully dissolved gelatin solution; continue heating to 58 ~ 61℃, and add reducing agent; until the chemical reaction in the silver nitrate solution is complete, the initial product of silver powder is obtained;C:Silver powder cleaning: add deionized water to the reaction kettle, clean and dry the finished silver powder, and obtain the finished silver powder.

- The preparation method of flake silver powder

Compared with spherical silver powder, flake silver powder has the following advantages:

1, Its conductive performance is good. The shape of silver particles is in close relationship with conductivity. Flake silver powders are arranged in chip structure, which has good liquidity. Because the contact is surface contact between the flake silver powder particles or line contact and the contact area of point contact is larger than the spherical silver powders, its resistance is relatively low, conductive performance is better.

2, It has high credibility. Because the spherical powder has the smallest activity of specific surface area and high surface energy, it has high degree of oxidation and oxidation tendency. And the specific surface area of the flake silver powders is opposite bigger than the low surface energy, it has low degree of oxidation and oxidation tendency. In addition, flake silver powder wide scope of torsion degrees and flexural crack stretching characteristics improve the reliability of electronic components.

3, It can save silver powder. With the same quality of flake silver powder and other shapes of silver powder coating, coating area of flake silver powder is largest; Therefore, using flake silver powder, on the one hand, can save the amount of silver powder, on the other hand, can reduce the thickness of coating, which is conducive to the miniaturization of electronic components.

1.The positive silver paste plays a crucial role in solar cells, and the silver powder plays a leading role in the positive silver paste. Silver powder is the conductive phase of positive silver paste, and its mass ratio can reach 80-92%, which has a great influence on the rheological property and printing property of paste, and plays a decisive role in the photoelectric conversion efficiency of solar cells. Current positive silver pulp with silver powder particle size distribution in 1 ~ 2 microns, usually it is easy to appear soft reunion phenomenon. It needs surface treatment by mechanical or chemical reagents. The surface treatment of aluminium powder can increase its wettability, affinity, and carrier increase printing performance and improve the flowing property of the thick liquid material, so the silver powder surface modification for solar battery positive silver pulp with excellent properties is very important.

2.Silver powder paint can not only resist corrosion and water, but also resist high temperature and rust. Silver powder paint will be dry in a moment after being used, which has a strong adhesion. So it is widely used in some heating equipment, vehicles, metal pipes, and some need to be anticorrosive metal surface and so on

3.Sterling silver application

Sterling silver is a beautiful silver-white metal with excellent ductility, electrical and thermal conductivity. Silver is often used to make highly sensitive physical instrument components. It is used to make a large number of contact points in various automation devices, rockets, submarines, computers, nuclear devices and communication systems. During use, each contact point needs to work millions of times. It must be wear-resistant, reliable and able to withstand strict working requirements. Silver can fully meet all kinds of requirements. If rare earth elements are added to silver, the properties are even better. The life of a contact point made with rare-earth silver can be extended several times.

The most important compound of silver is silver nitrate. In medicine, aqueous solution of silver nitrate is commonly used as eye drops.

Electrical and electronic equipment is the industry with the largest amount of silver, its use is divided into electrical contact materials, composite materials and welding materials. Silver and silver-based electrical contact materials can be classified into pure silver, silver alloy, silver-oxide and sintered alloy. Worldwide annual output of silver and silver-based contact materials is about 2,900 ~ 3,000 tons. Composite materials are prepared by composite technology, including silver alloy composite materials and silver matrix composite materials. From the perspective of silver saving technology, silver composite materials are a new kind of materials with great development prospects. Silver welding materials include pure silver solder, silver, copper solder, etc.

5.Light-sensitive materials

Silver halide photosensitive materials are one of the fields with the largest amount of silver. At present, photographic film, photographic paper, X-ray film, fluorescence information documentary, electron microscope photographic film and printing film are the most important photographic materials. Due to the development of electronic imaging and digital imaging technology, the amount of silver halide photosensitive material has been reduced, but the application of silver halide photosensitive material is still irreplaceable in some aspects, and there is still a large market space.

6.Chemical materials

Silver has two main applications in this regard, one as a catalyst, such as widely used in REDOX and polymerization reactions, for the treatment of sulphide containing industrial waste gas.The other is used in electronic electroplating industrial preparations, such as silver slurry, potassium cyanide, etc.

7.Craft ornaments

Silver has attractive white luster, high chemical stability and collection value, favored by people, so it has the reputation of "women's metal", which is widely used as jewelry, ornaments, silverware, tableware, congratulatory gifts, MEDALS and commemorative COINS. Silver jewelry has a broad market in developing countries, and silver tableware is welcomed by families. The silver commemorative coin is beautifully designed, with a small circulation, and has the function of maintaining and increasing value, which is highly appreciated by coin collectors and coin investors.

Silver ions and compounds are toxic to some bacteria, viruses, algae and fungi, but are almost completely harmless to humans. This bactericidal effect of silver allows it to kill living organisms in vitro. However, testing and standardizing silver products is difficult.

Silver is being used in new applications as a versatile antimicrobial agent. One is to dissolve silver nitrate in alginate to prevent infection of wounds, especially burn wounds. Silver-coated glass have good antibacterial properties. In addition, the food and drug administration (FDA) has approved the use of a silver-coated airway that studies have shown to be effective in reducing airway pneumonia.

Silver is not toxic to the human body, but long-term exposure to silver metals and non-toxic silver compounds can also cause silver deposit. Because the body pigment changes, the skin surface will appear gray-blue. Although not toxic, it can still affect the appearance.

TRUNNANO (Luoyang Trunnano Tech Co., Ltd ) is a professional Silver powder manufacturer with over 12 years experience in chemical products research and development. If you are looking for high quality Silver powder, please feel free to contact us and send an inquiry.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- What is Cadmium telluride CdTe and CdTe solar cell?

- Four types of surfactants and their differences and applications

- What is the explosive welding cladding of metal plates?

- What is EBS Ethylene Bis Stearamide?

- An article lets you understand the characteristics and applications of sodium silicate

- Advantages of graphite anode for lithium-ion battery

- What is Spherical Quartz Powder?

- What is sodium silicate?

- Characteristics and Application of Spherical Alumina

- Application of Manganese Dioxide

CATEGORIES